Product Description

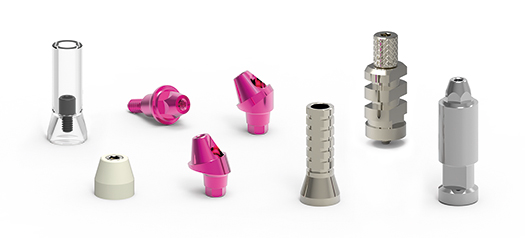

The prosthetic components are characterized by a colour coding that makes the corresponding connection platform easily identifiable:

YELLOW: Mini Conical Connection for 3.0 mm Narrow implants

FUCHSIA: Standard Conical Connection for 3.5 - 4.0 - 4.5 - 5.0 - 5.5 - 6.0 - 6.5 mm Regular and Wide implants

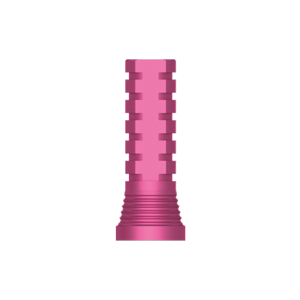

The temporary abutment, available in rotational and antirotational

versions, is used for temporary prostheses also for immediate

loading on a single tooth.

Its easy changeable length and retaining grooves make it ideal for

bonding.

The milling abutment joins the advantage of narrow industrial

production tolerances to the versatility with which to customize the

shape of the abutment to adapt to different anatomic situations.

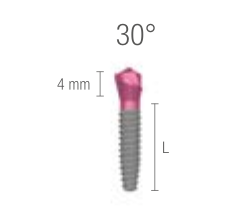

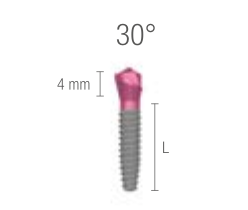

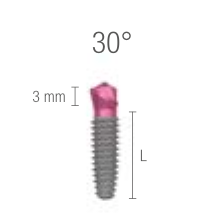

There are straight and angled abutments featuring different

chamfer heights to provide a variety of solutions to deal with the

most varied anatomic situations. The implant-abutment connection

area is realized with a 10 microns tolerance.

The castable abutments are made of PMMA

(polymethylmethacrylate), an easy workable castable transparent

resin ideal for the construction of structures and temporary

elements. PMMA allows for casting results completely free of

contamination.

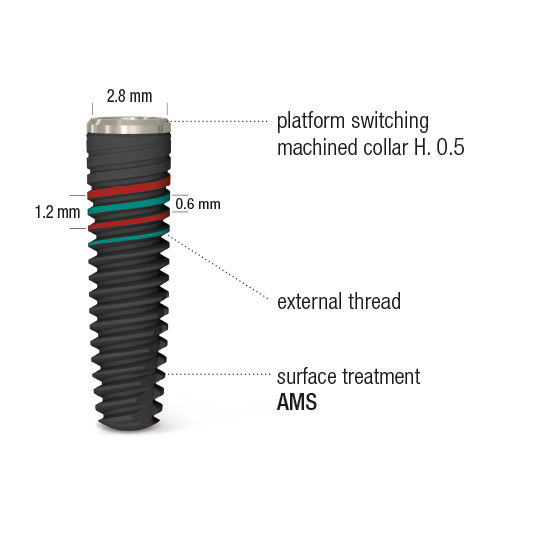

All the PSK Line prosthetic screws undergo a coating process

called Black Diamond to reduce the friction coefficient during

the screwing phase. Thanks to the better tightening process, the

annoying connection loosening incidents are minimized.

The ideal tightening torque for K1 prosthetic screws is 20 Ncm. This torque value, without creating unnecessary stress in the conical part of the implant, ensures the activation of the conicity between

the implant and the abutment with the well-known advantages of anti-unscrewing and minimizing the risk of bacterial infiltration.